highlights

Design Assist Services enabled faster design analyses, price iterations and optimizations.

Construction Services provided better cost information throughout the project lifecycle.

Automated design to fabrication.

Enhanced collaboration processes allowed for optimized design and accountability.

OVERVIEW

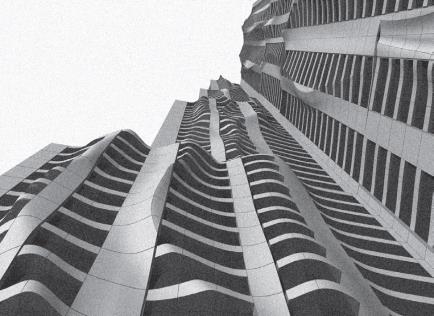

The Beekman Tower is set on a 4.000 sqm site in lower Manhattan. The building is a 75-story mixed-use tower, which houses a New York City Public School, office space for the New York Downtown Hospital, and over nine hundred residential units.

The classical proportions of the tower are conforming to the New York City setback rules creating a tall wedding cake design typical in the city. The wall of the tower undulates in soft folds reminiscent of fabric. The apartment windows perforate this sculptural stainless steel cladding. Each floor of the tower has a unique configuration, due to the undulating facade. Each residential unit will have a unique shape where it connects with the exterior façade. Trimble Consulting provided the technical infrastructure and services integrating the process from design through the supply chain management.

Client:

Forest City

Ratner

Location:

New York, USA

Type:

Mixed-Use Tower

Size:

93.000 sqm

Team:

Gehry Partners, WSP Cantor, Seinuk, JB&B

Outcomes

Trimble Consulting worked with the client to improve the design process, automate design to fabrication, accelerate collaboration, create accountability and optimize the design.

The Beekman Tower is informed by specific programmatic issues in the layout of individual panel elements, and by the specific economic requirements of developing the design intentions into a mass customizable panelized curtain wall system.

The goal of the automation process was to develop custom tools which would allow designers to modify the surface qualities while incorporating the cost variations of specific panel typologies into an overall development of the panelization. The result was an overall façade design incorporating fabrication logics and associated unit costs of different panel geometries into a solution that satisfies the overall design intentions of the surface geometry, the detailed construction logic of each panel, and both micro and macro cost metrics.